/ References / Töreboda

Daloc 2MW

Conversion from fossil oil to bioenergy for one of Sweden’s major door manufacturers. The plant consists of two factories connected by a district heating culvert.

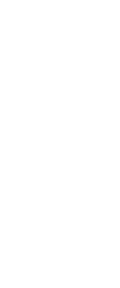

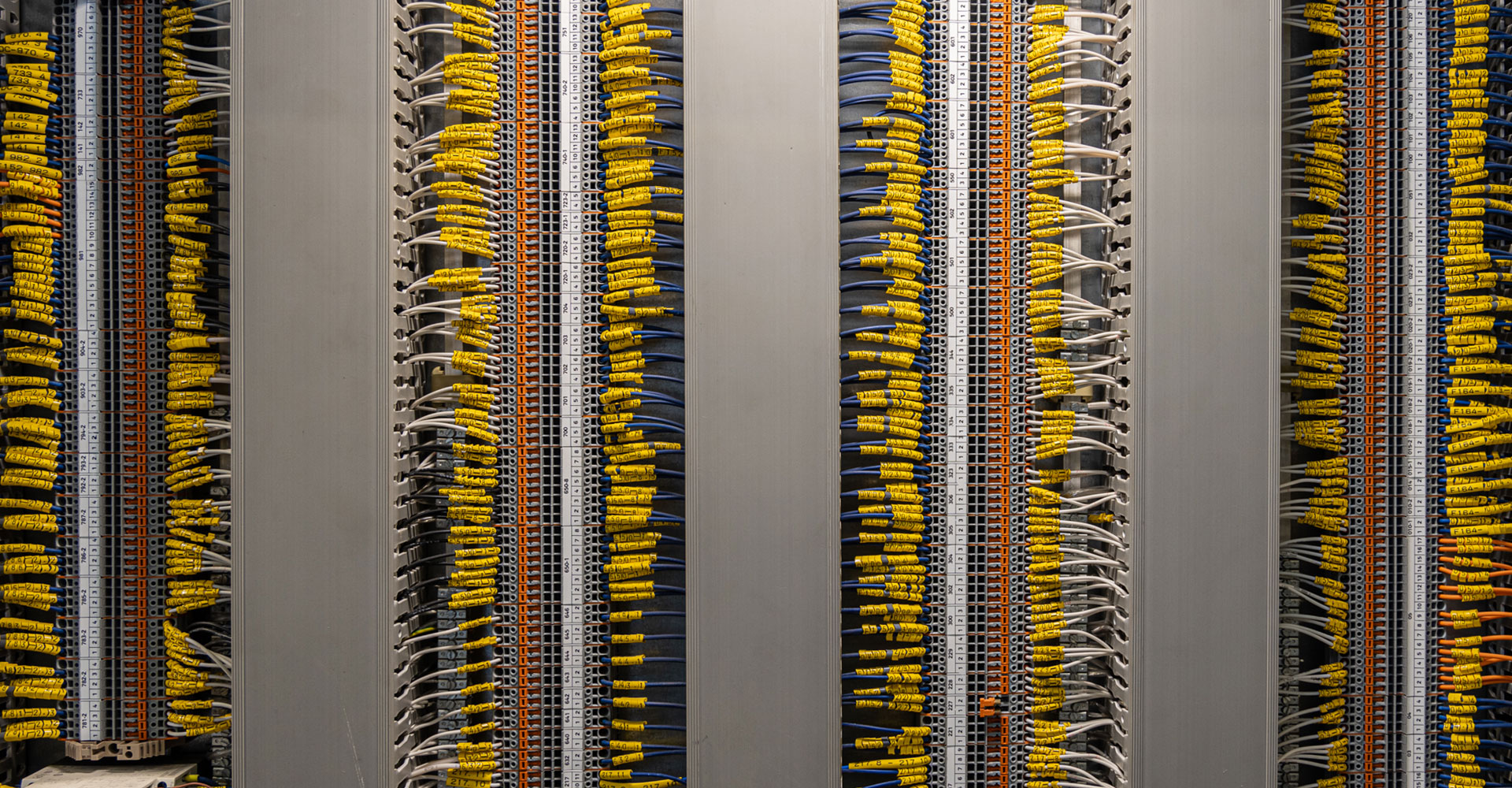

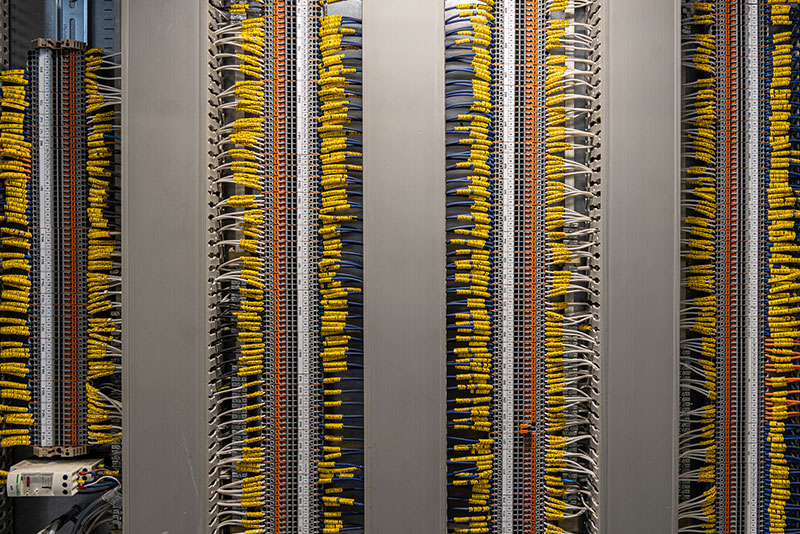

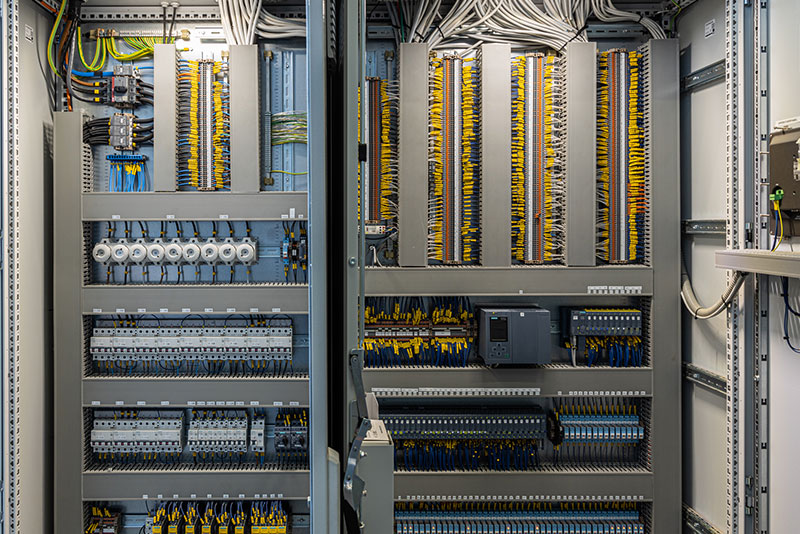

A new bio-boiler has been built that uses residual products from production in the form of wood briquettes. The combustion equipment is therefore carried out with AKJ’s advanced combustion and control systems in combination with NOx reduction equipment SNCR (Selective Non Catalytic Reduction) and flue gas cleaning equipment with electrostatic precipitators.

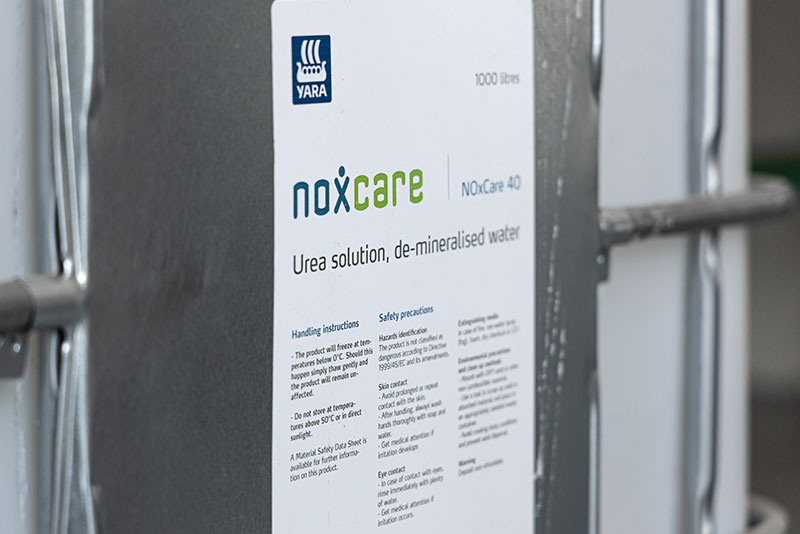

The plant was adapted to optimize operational availability, environmental performance and is also being prepared for electricity generation by ORC (Organic Rankine Cycle) turbine.

The delivery included a biofuel-fired hot water boiler, fuel feed, electrical, control and piping installations and flue gas cleaning.

Project information

Project information

Construction

Briquette boiler

Power: 2MW

Fuel

Glued laminated timber with high nitrogen content, residues from production

Purification

MC & electrostatic precipitator

Environmental requirements

<50 mg/Nm3 dust

<300 mg/Nm3 NOx

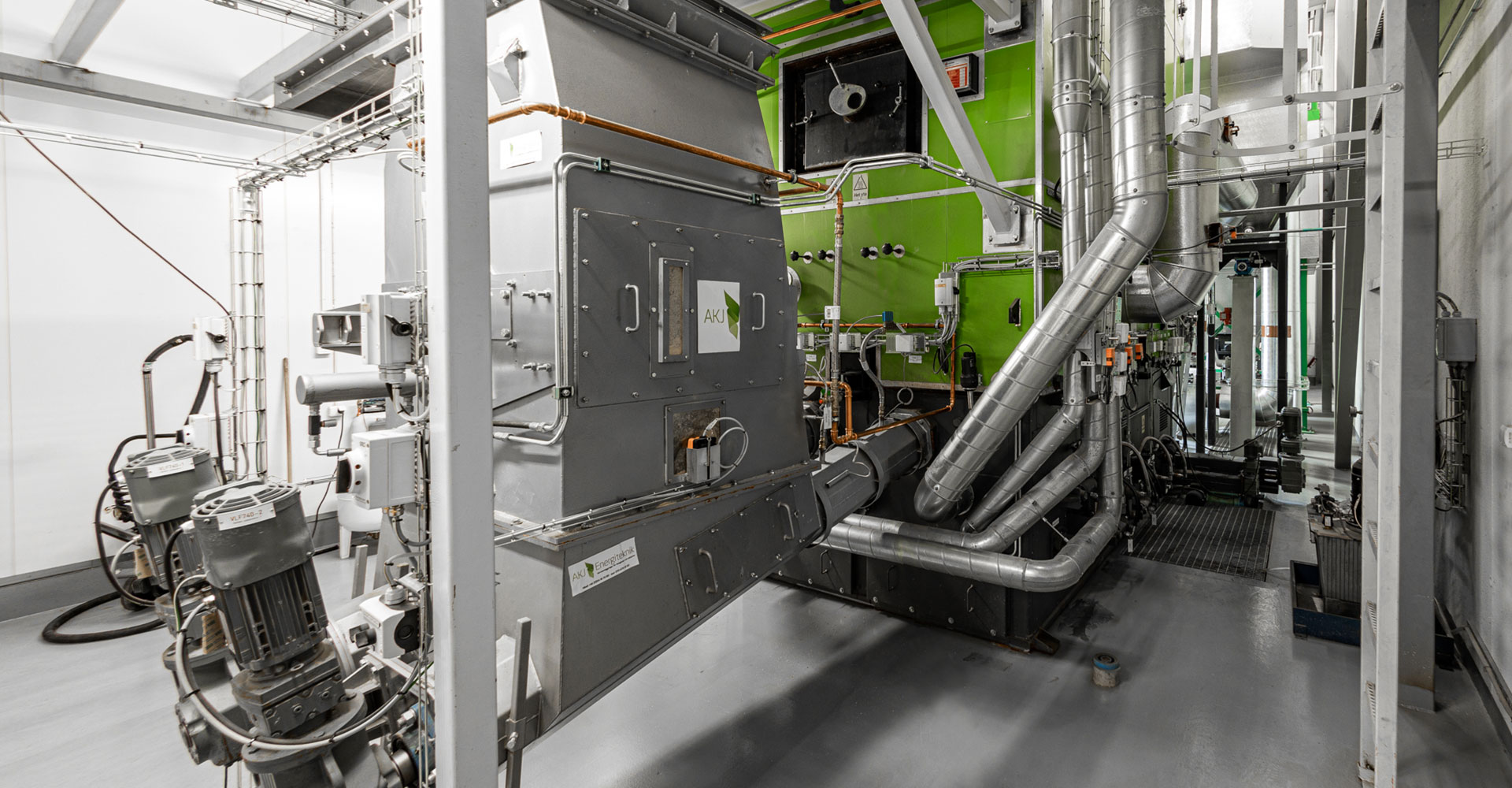

NOx reduction

The combustion equipment features AKJ’s advanced combustion and control systems combined with Selective Non Catalytic Reduction (SNCR) NOx reduction equipment.

Challenging fuel

As fuel, residual products from door production are used, which contain high nitrogen content, resulting in high Nox emissions.

But thanks to AKJ’s good combustion together with SNCR, emission levels are kept below current limits.

“The plant is equipped with AKJ’s advanced combustion and control systems”

Contact person

Passion for Bioenergy

and Sustainable

Energy Solutions.

Passion for Bioenergy

and Sustainable

Energy Solutions.